Laboratory- Analyzers & Tools

QA Equipment

01

SCHATZ

Verify the coefficient of friction based on customers' requirement.

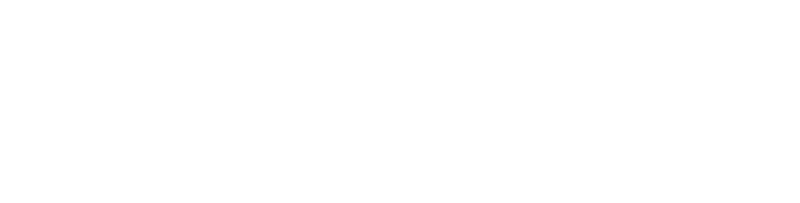

02

X-ray

Final inspection of the palted metal thickness.

the thickness of zinc layer and mass percent of nickel for zinc-nicked plated parts

03

AA

Inspect specific metal contents in plating bath.

04

NSS

Salt spray tests

Per ASTM B117 / ISO 9227

05

Titration

Check the concentration of each plating solution

06

Moisture Analyzer

Check the solid content of the sealing.

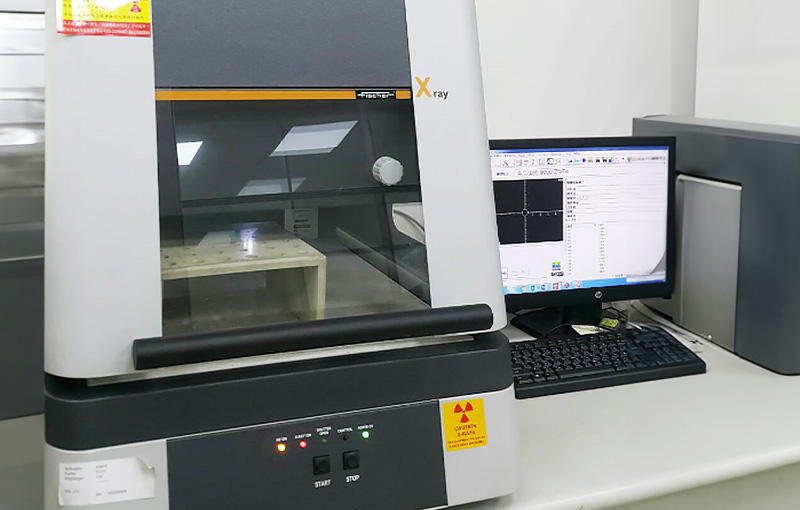

07

Hull Cell

The Hull Cell anylysis is for measuring the condition of plating bath by simulate plating tank environment with the help of standard panel.

08

UV Light

Check UV Tracer

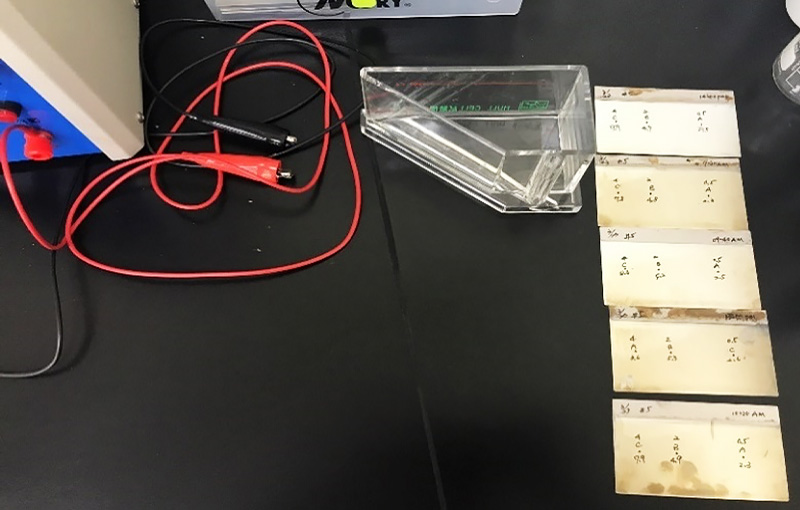

09

Gauge/Curvature measurement

Pre-process/Final inspection of dimensions

10

Oven

Adhesion Test

Thermal shock test